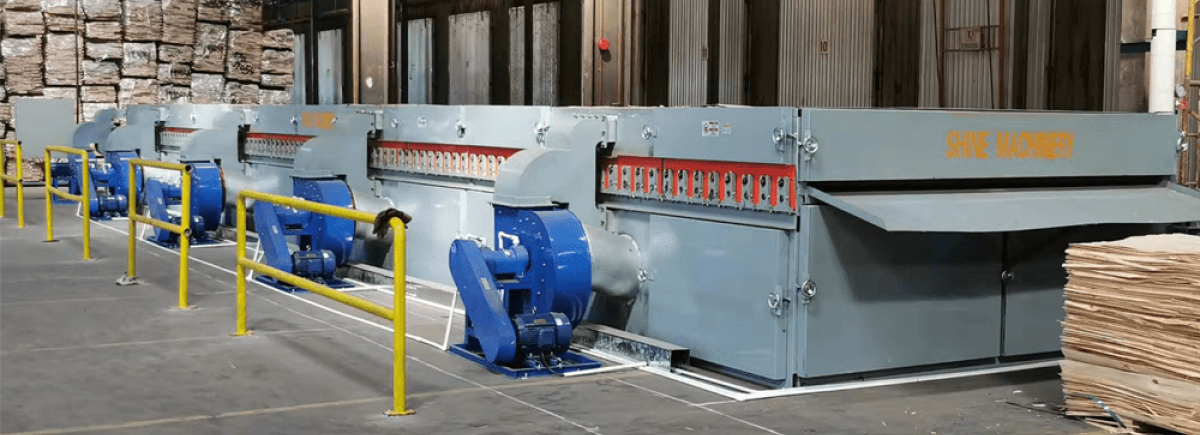

Product Description

The veneer roller dryer is one of the important veneer drying machines in the plywood and veneer making process. It is designed especially for the Core Veneer drying and is the Dryer of choice all over the country as well as abroad. The veneer roller dryer utilizes the latest international pressurized contact technology and the veneer is pressed and moved forward while ironing at the same time. The steam veneer roller dryer consists of feeding, heating, cooling, and discharge sections. Also, the veneer roller dryer can run on a biomass burner.

Main Technical Specifications

|

||||||||||||||||||||||||||||||||||||||||||||

Our Advantages

1. The integrated design of the veneer dryer can greatly improve the utilization rate of the space occupied. The veneer making enterprises can do the drying all the time, which can avoid the wet veneer deterioration due to climate, improve the drying quality effectively.

2. High-temperature rollers directly contact with wet veneer for heat transfer, and the heat efficiency is high, heat loss is reduced.

3. The veneer after drying has uniform MC, flat without a split, no buckle or end waviness, the surface is in good condition for gluing, and avoid collapse and honeycomb.

4. The automatic electric control system and frequency conversion system can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve an ideal drying effect.

5. A one-time investment of the equipment is small, highlights the performance-to-price ratio superiority.

6. It is a new concept of high-tech products, which can solve the major problems during the drying process efficiently including difficult to dry, drying cycle is long, drying uneven, easy to crack, deformation, and low yield of wood and others.

7. Less maintenance is required for this type of Dryers with no Veneer Jamming leading to lesser Downtime.

8. We have a professional R&D team that can make customized designs according to customer’s special requirements.

9. After-sales service: remote operation is available on request, Network interactive services, regular customer visits, the skilled service team can solve the failure the first time.

Project Cases

Other Matching Products