Product Description

The 10 Sections 2 Layers Wire Rope Veneer Dryer has the production capacity of 3m3/ h. Continuous Face veneer wire rope dryer is one of the main machines in plywood production used to dry the veneer with thickness less than 1.5mm. It consists of front driving frame and back driving frame, heating area and cooling section. The heating area is divided into several sections, and usually each section is 2 meter in length. This machine is customized according to the specific production capacity.

Specifications

|

Features

1. The wire ropes type veneer dryer is the main equipment in the production of plywood.

2. It is composed of four parts, which are divided into Feeding area, heating area, cooling area and discharging area.

3. It is mainly used for drying core veneer, partial surface and bottom plate.

4. It has high efficiency, low energy consumption, and lower cost, which can better meet the production process of the product.

5. Low professional requirements for workers.

6. This type of dryer can be used for veneers with low flatness requirements.

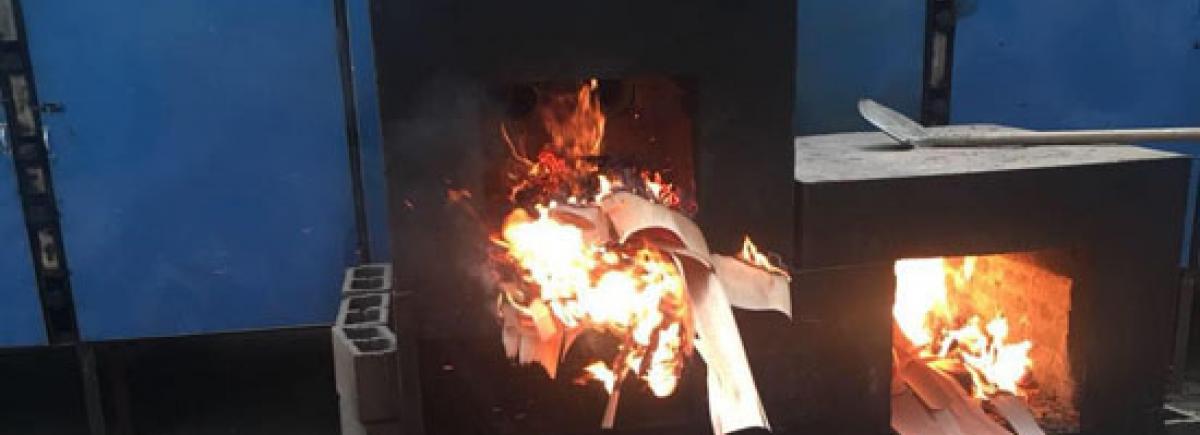

7. The heat source is a hot air stove 900,000 kcal(coal and waste wood) and the heating source can be changed according to the requirements of different customers.

8. We can design the veneer dryer as customer`s project requirement.

9. The length and layers of our veneer dryer can be customized according to your production capacity.

Project Cases