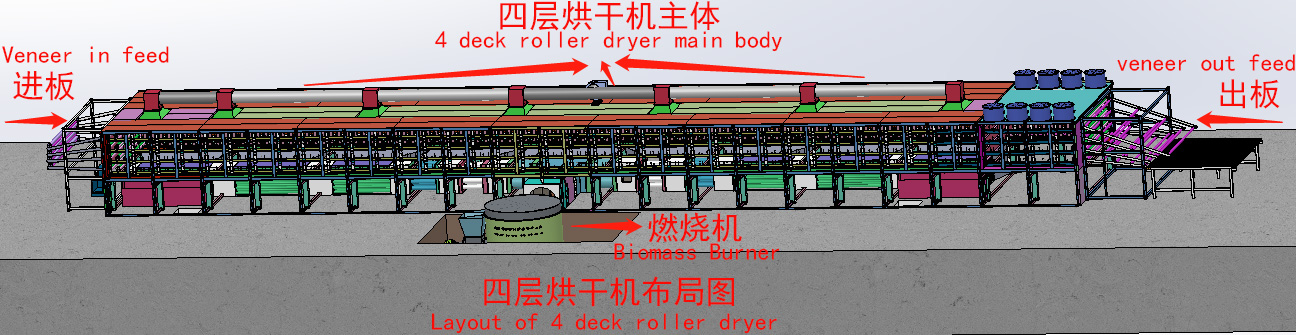

Working Principle of Veneer Dryer

Shine Biomass Veneer dryer is product in the design of the continuous roller pressure type of hot air cylinder,it is using the most advanced continuous pressurized contact and its working principle is veneer veneer drying technology in steel tube under the clamping roller,two by preheating the oven temperature to 140,and then enter the upper and lower roller and through the hot air pipe to the single board upside down between hot high pressure blowing for quick dry,so you can make the veneer smooth moisture content after drying of uniform,And it has the characteristics of high temperature roller and wet veneer direct contact heat transfer, high thermal efficiency and small thermal loss.

Main Features and Advantages of Shine Roller Veneer Dryer

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Shine core veneer dryer or face veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

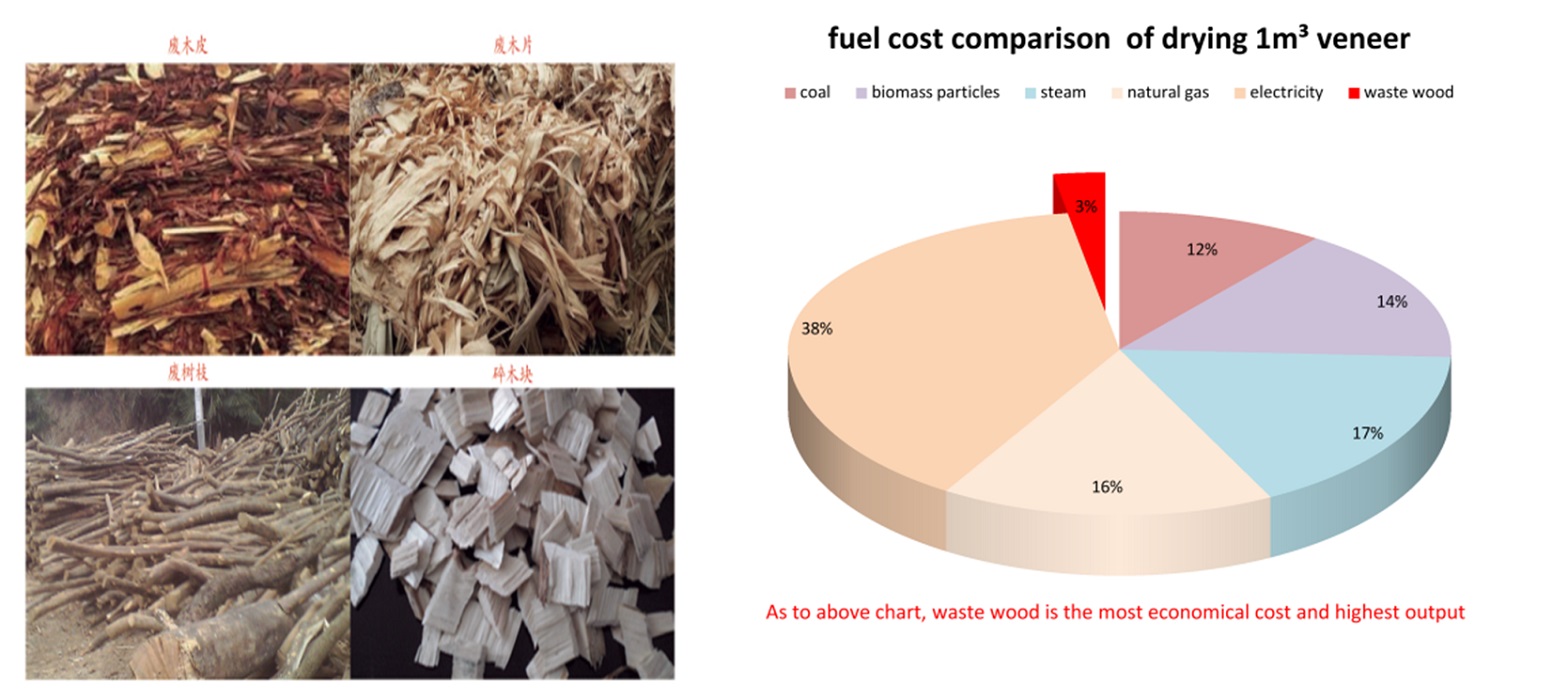

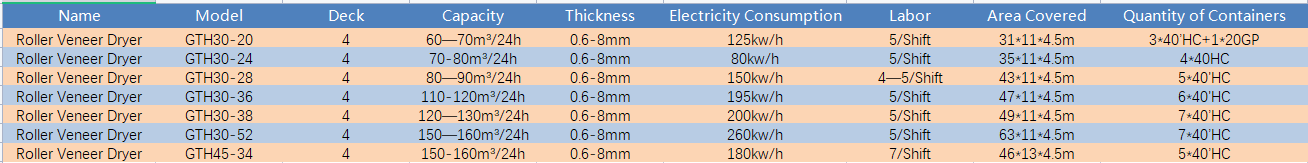

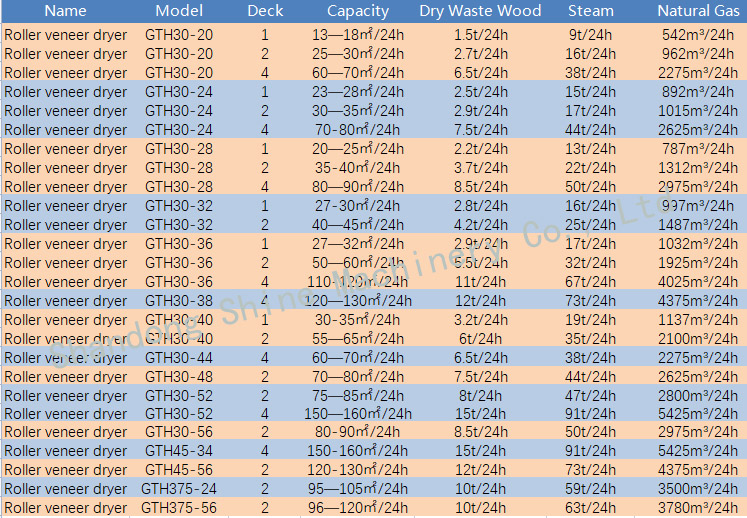

4.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark ,which can reduce the fuel cost greatly for the user.

Product Parameters

Customer case

Customer Visit and Factory

Certification

Product Packaging