Product Introduction

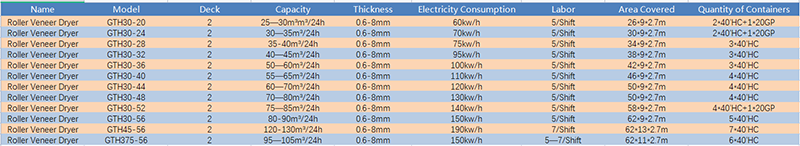

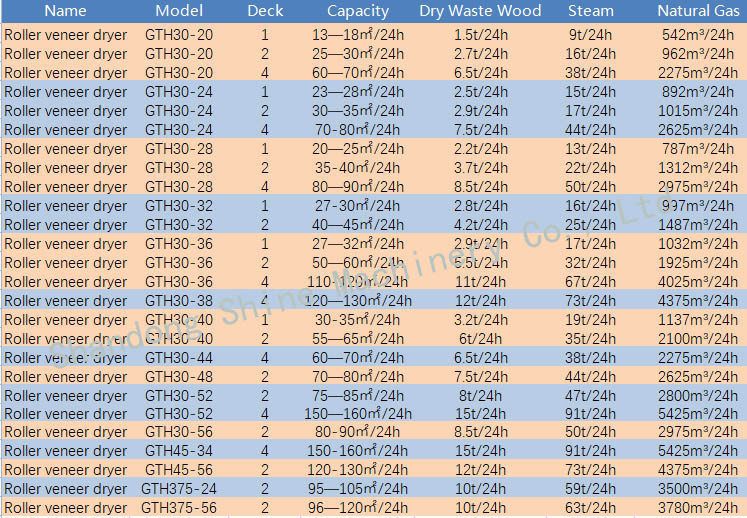

Roller veneer drying machine has an advanced heat exchanging structure with features of high heat exchange efficiency and low heat loss.The core veneer dryer can be heated by a steam boiler,thermal oil heater, or biomass burner which can save the fuel cost the most.Shine veneer dryer adopts automatic electric control and frequency conversion system,which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect.Equipped with automatic veneer feeder and automatic collection system,which not only improves the drying efficiency but also saves labor cost mostly.

Main Features and Advantages of Shine Roller Veneer Dryer

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Shine core veneer dryer or face veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark ,which can reduce the fuel cost greatly for the user.

Product Parameters

Customer case

Customer Visit and Factory

Certification

Product Packaging