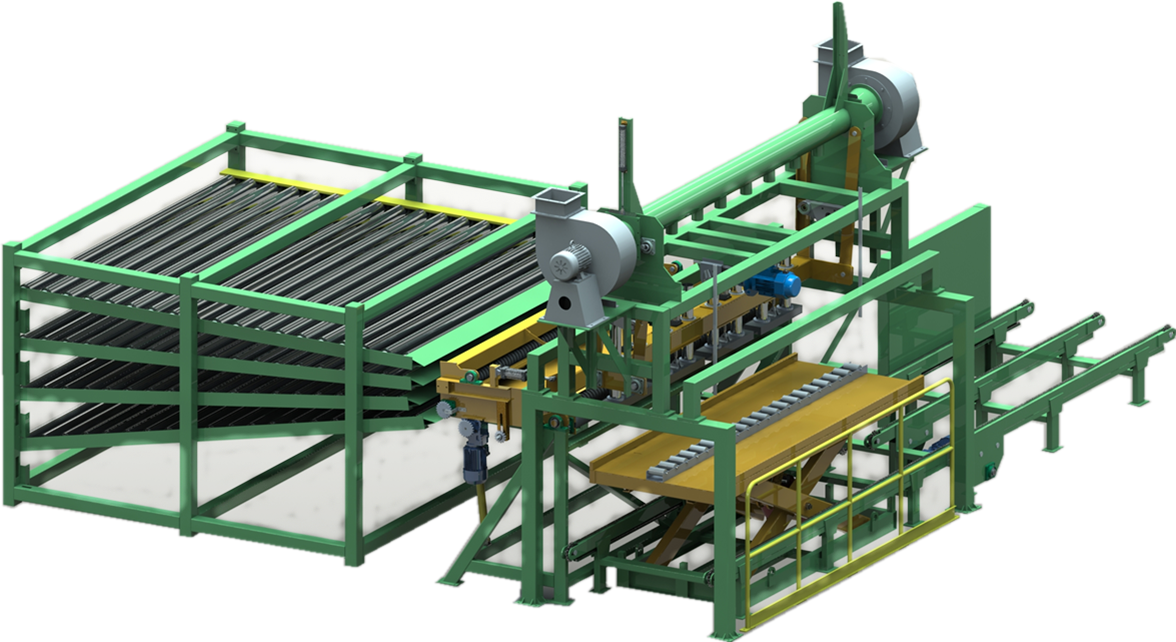

40M 2 Deck Roller Veneer Dryer Machine

Shine veneer roller dryer can keep the veneer smooth after drying. For 40m 2 deck veneer dryer machine, we equipped with water circulation system, which can save energy and improve efficiency. Biomass burner as heat for 40m 2 deck veneer drying machine, bark and other tree waste can be used as the fuels for veneer drying line, saving fuel cost significantly. The drying capacity of 40m 2 deck dryer can achieve 2.5m³ per hour. The composite cost of Shine biomass veneer drying machine is only USD 6-12/per cubic meter.

Main Technical Parameters

|

||||||||||||||||||||||||||||||||||||||||||

40M 2 Deck Roller Veneer Dryer Machine Advantages

1. Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect.

2. The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost to the most.

3. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

4. The veneer after drying is free of splits and the surface is in good condition for gluing.

5. Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

6. Automatic electric control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are international famous brands.

7. Shine veneer dryer adopts frequency conversion, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect.

Project Cases

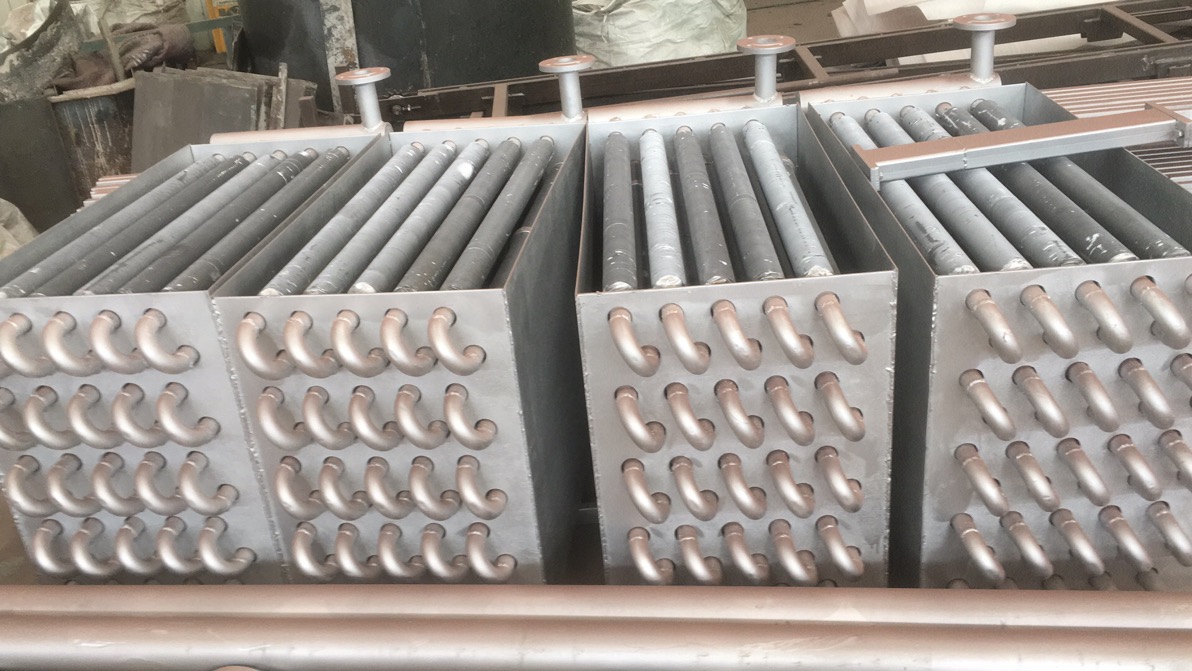

Other Matching Products