Product Description

Shine 3 deck veneer drying machine is a new type of product for veneer drying, which has high drying capacity. The veneer dryer machine is equipped with a roller material φ102 seamless steel pipe. The bearings installed on the dryers are featured high temperature 500 degrees Celsius resistance and low temperature -20 degrees Celsius resistance. Furthermore, no need for maintenance in daily operation. The 20m 3 deck veneer dryer can dry about 60m³ for 24 hours per day. Besides, Shine veneer roller dryer is installed with automatic feeding and the collecting system, which has a higher drying capacity than the double-deck veneer dryer machine while a more favorable price compared to the 4 deck layers. The 3 deck veneer roller dryer is heated by biomass burner which can directly burn waste wood to heat air and in this way the fuel cost is reduced to the most. The veneer roller dryer is also available on a steam boiler or thermal oil heater.

Technical Specifications and Parameters

|

Main Advantages of 3Deck Veneer Dryer Machine

- Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost, and perfect drying effect. The composite cost is only about $6 -12/cubic meter, which can improve customers' profit space greatly.

- The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost mostly. Compared to steam type or heat conduction oil type veneer dryer, the drying cost is reduced greatly.

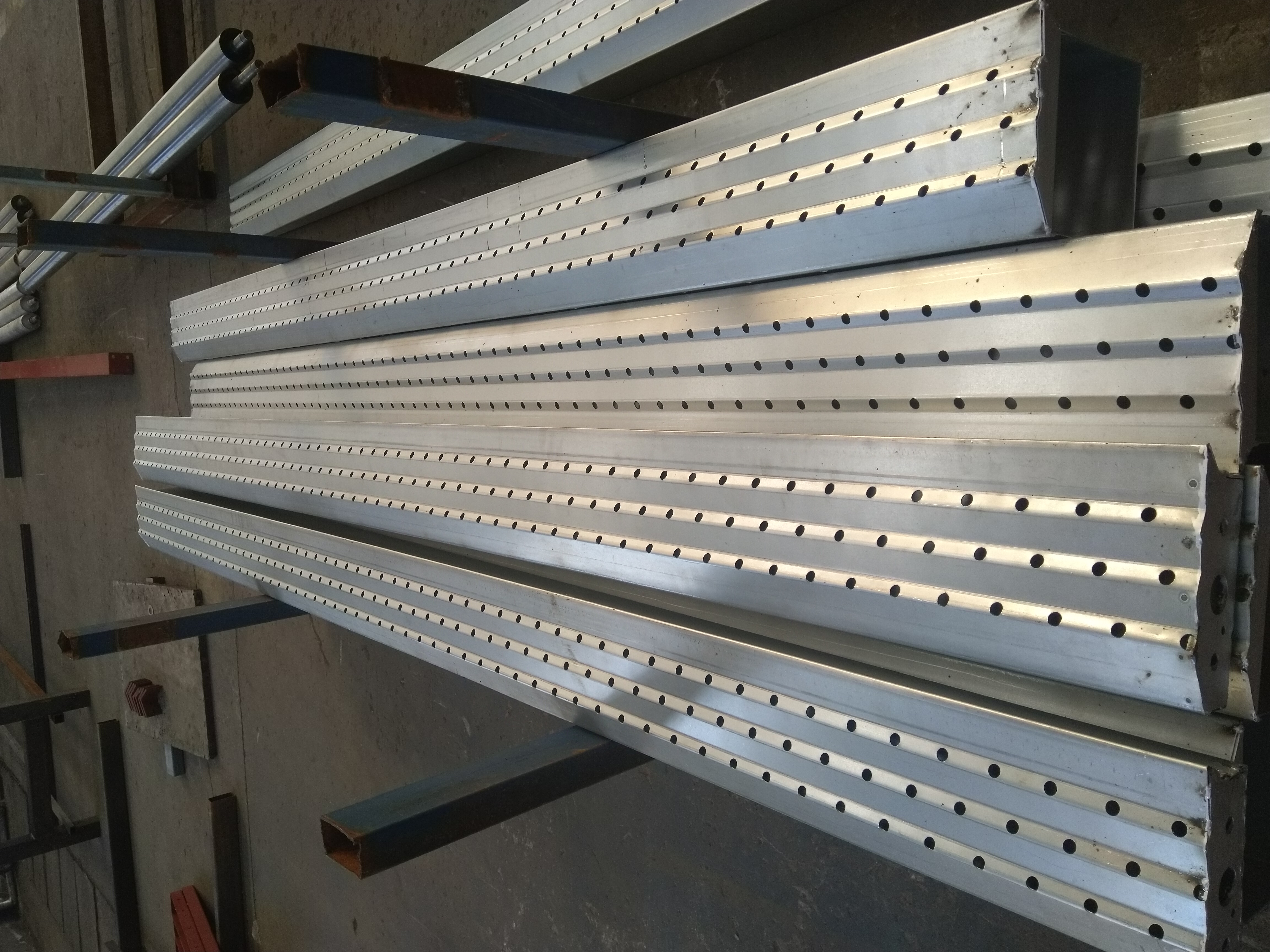

- SHINE heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. The veneer after drying has a uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

- Shine veneer dryer adopts automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve an ideal drying effect. Equipped with automatic veneer feeder and automatic collection system, which not only improves the drying efficiency but also saves labor costs mostly.

- We have a professional R&D team that can design different models according to customer’s special requirement. Perfect after-sale service system can supply 24h online service, remote operation is available on request, regular customer visits, sufficient spare parts supply in time.

- Roller material is φ102 seamless steel pipe which stands for better quality.

- Automatic temperature control and speed regulation system can guarantee consistent moisture content.

- The bearings installed for the dryers are featured high temperature 500 degrees Celsius resistance and low temperature -20 degrees Celsius resistance. Furthermore, no need for maintenance in daily operation.

- The temperature in the heating chamber of the biomass burner heated veneer roller dryer is 40-60℃ higher than the steam or thermal oil type veneer dryer, which shortens the drying time and increases the capacity greatly.

- The automatic feeding and collection system improves the production efficiency and saves the labor cost to the most.

- 3 deck veneer dryers machine has features of high productivity, energy-saving, and environmental protection.

- The veneer drying machine has the minimum electrical and fuel consumption, maximum production, quality than the best, and energy-efficient as well.

- The drying capacity is improved greatly by using the continuous 3deck veneer dryers.

Project Cases

Other Matching Products