28M 2 Deck Veneer Dryer Running on Biomass Burner

Shine 28m 2 deck wood veneer dryer is composed of 24m heating section and 4m cooling section. The fresh veneer is fed into the dryer and moved through the dryers by running rollers and at the same time the hot air blows the surface and back of the veneer to achieve the right drying effect. The drying capacity of 28m 2 deck dryer can achieve about 1.5m³ per hour. So the heat efficiency is high, heat loss is reduced. The veneer after drying has uniform moisture content, flat without buckle or end waviness and the surface is in good condition for gluing.

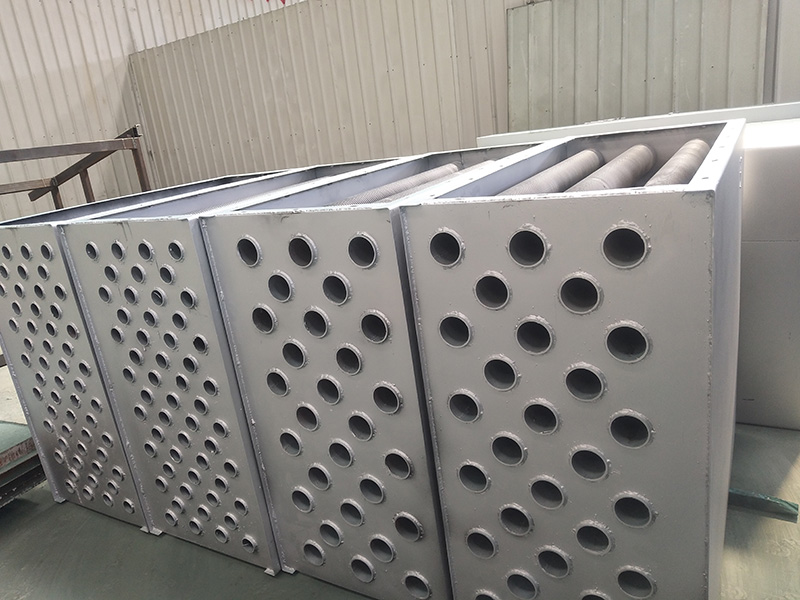

4 Ton Biomass Burner Introduction

Equipped with 4 ton Biomass Burner, which is the exclusive patent invented by Shine Machinery. It has the advantages of high efficiency, low fuel consumption and energy saving. The working principle of Biomass Burner is to produce high temperature by burning waste wood (mainly from rotary cutting veneer, waste bark and waste veneer) directly, heating air and delivering to the dryer. The fuel cost is much lower than thermal oil, steam gas, electricity and others. The composite cost is only about$6 -12/ m³.

Main Technical Parameters

|

||||||||||||||||||||||||||||||||||||||||||

28M 2 Deck Veneer Dryer Advantages

1. Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect

2. The veneer after drying has uniform moisture content, flat without buckle or end waviness and the surface is in good condition for gluing.

3. Automatic electric control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are international famous brands.

4. Shine veneer dryer adopts frequency conversion, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect.

5. Less maintenance is required for Shine veneer dryer and no veneer jamming leading to less downtime.

Project Cases

Other Matching Products