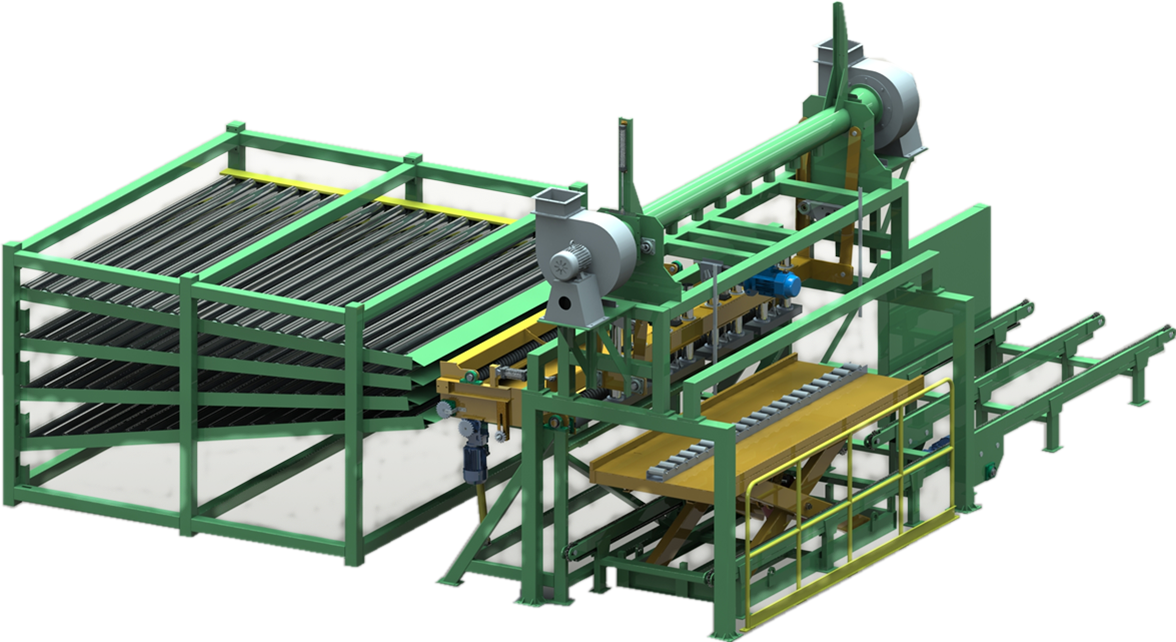

24M 4 Deck Biomass Veneer Drying Machine

Shine 24m 4 deck veneer dryer has low power consumption and small floor space, which can be used in small and medium plywood factories to dry the core veneer. 24m 4 deck wood veneer dryer is composed of 20m heating section and 4m cooling section. The drying capacity of 24m 4 deck dryer can achieve about 95-100m³ for 24 hours per day. The veneer roller dryer allows automatic feeder devices, which can save labor costs greatly. Equipped with biomass burner, all kinds of waste wood such as waste bark, the waste veneer can be burned as fuel directly, even the waste wood is wet. The temperature inside our wood veneer dryer is enough to reduce moisture content. Shine 24m 4 deck biomass veneer drying machine can ensure perfect drying effect and reduce drying cost mostly.

Main Technical Parameters

Model No |

GTH30-24 |

Working Width |

3000mm |

Roller material |

Q235B,φ102 seamless steel pipe |

Number of sections |

12 |

Number of decks |

4 |

Heating area length |

10m |

Cooling area length |

4m |

Veneer thickness |

0.6-8mm |

Veneer water moisture |

From about 50-80% to about 10% |

Heating material & drying temperature |

Waste wood, 140-200℃ adjustable. Temperature control accuracy ±5℃. There is automatic temperature control and speed regulation system ,which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) |

4.5m³/h |

Veneer transport speed |

5-22m/min,16A chain |

Hot air blower |

Power:5.5KW(10pc) |

Traction motor |

Power: 4KW(3pc) |

Cold air blower |

Power: 5.5KW(2pc) |

Air intake fan |

Power : 11KW(1pc) |

6 ton biomass burner |

Power: 20KW |

Automatic veneer feeding system (optional) |

Power :24.2kw |

Automatic Veneer collecting system (optional) |

Power :6.2kw |

Total power |

139.4KW |

Actual electricity consumption |

About 95kw per hour |

24M 4 Deck Biomass Veneer Drying Machine Advantages

1.Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. The composite cost is only about $6 -12/cubic meter, which can improve customers’ profit space greatly.

2.The bearings of 4 deck veneer dryer are featured high temperature 500 degree Celsius resistance and low temperature -20 degree Celsius resistance, which no need inject oil and easy maintenance in the daily operation.

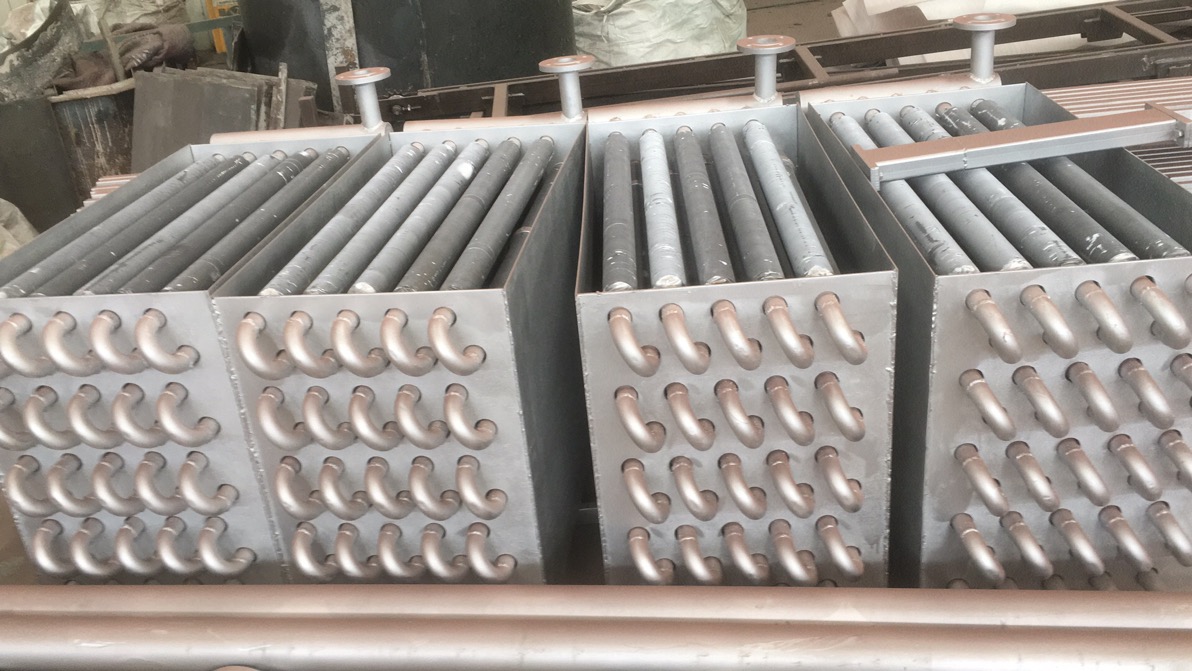

3.Shine heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger is different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. The veneer after drying has uniform moisture content, flat, no buckle or end waviness, free of splits and the surface is in good condition for gluing.

4. Shine veneer dryer adopts automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve ideal drying effect. Equipped with automatic veneer feeder and automatic collection system, which not only improves the drying efficiency but also saves labor cost mostly.

5.The veneer after drying has uniform moisture content and it is flat without buckle or end waviness, free of splits and the surface is in good condition for gluing. Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

6.We have a professional R&D team that can design different models according to customer’s special requirement. Perfect after-sale service system can supply 24h online service, remote operation is available on request, regular customer visits, sufficient spare parts supply in time.

Project Cases

Other Matching Products