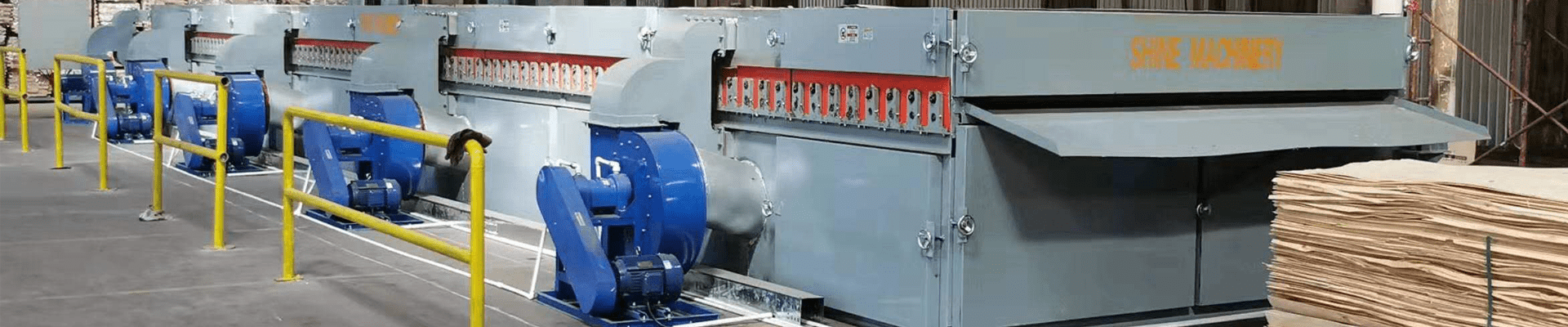

3Deck 26M Mesh Belt Veneer Dryer Machine

Veneer drying line is important machine in plywood processing. When you peeling get fresh veneer, for long stock, need remove water and moisture, so you need core veneer dryer or drying line. Shine 3 deck veneer dryers have the salient features of higher price performance ratio, higher drying capacity. 26m 3 deck mesh belt dryer is suitable for drying thin face veneer, which can dry 2-3m³ veneer per hour. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.