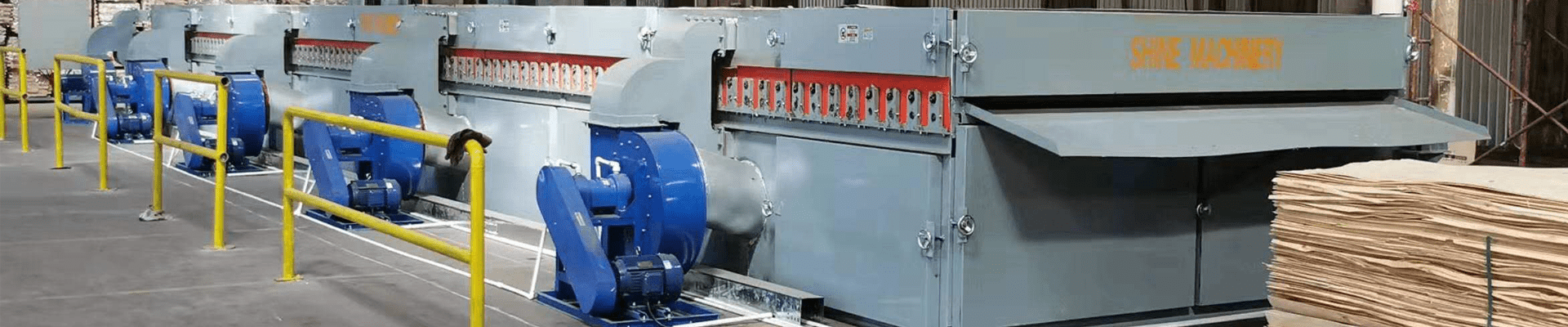

Four layer 38 m veneer roller dryer and 10 ton stove

The 4 Deck 38M Biomass Burner heated Veneer Roller Dryer has the drying capacity of 4.5m3/h. The total production cost(labor, fuel and electrictiy power) is only USD6-USD12 per cubic meter by utilizing the biomass burner as the heat source. The automatic feeder and collection system are installed with the 4 deck veneer roller dryer which saves the labor cost greatly and improves the feeding and collecting efficiency. FYI, the 3 deck veneer dryer can run on steam boiler or thermal oil heater too.