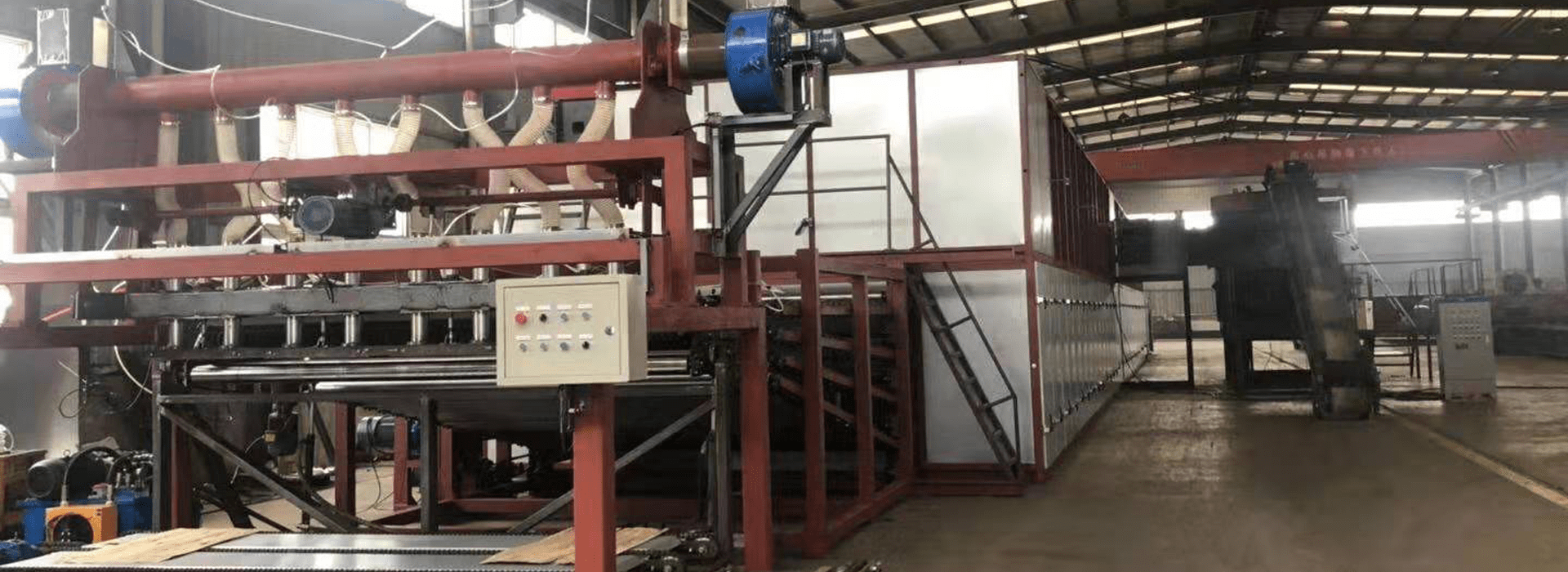

4 Deck 28M Veneer Roller Dryer Running on Biomass Burner

The drying capacity of 4 deck 32m veneer dryer running on Biomass Burner can achieve 6m3/ h. The biomass burner is our patented product and it can burn waste wood directly to heat air and supply to the dryer. The composite drying cost is only USD 6-12/m³.